Our structure

Atomat has a complete workshop with dozens of machines, most of them manufactured by the Atomat group, to serve the most diverse and demanding services in the steel market, among others.

Grinding Machines

CNC machines dedicated to grinding services in tungsten carbide and other high wear resistant metals, serving services from guide rollers to hard metal jacketed cylinders.

ATOMAT AT710 E CNC – Parts up to Ø380mm x 700mm between points.

ATOMAT AT706 – Dedicated to the grinding of roll sets for microcassettes.

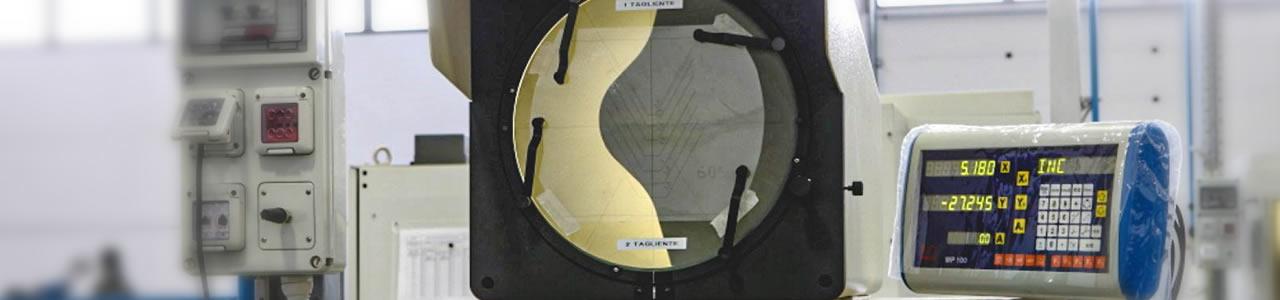

Notch and Marking Machine

CNC machines dedicated to notch and marking logos on tungsten carbide cylinders and rolls for the lamination area.

AT820 E CNC – Parts up to Ø500mm x 2500mm between points.

AT811 E CNC – Dedicated to notch and marking finishing rolls

Lathe

CNC machines dedicated to machining and recalibration of rolling cylinders, have CAM software, facilitating operations that demand greater precision.

AT830 E CNC – Parts Up to Ø720mm x 3450mm between points.

Quality

Atomat has a wide structure, with equipment for dimensional and geometric profile measurement, meeting the tolerances required by the customer’s process.