Rolling Bearings

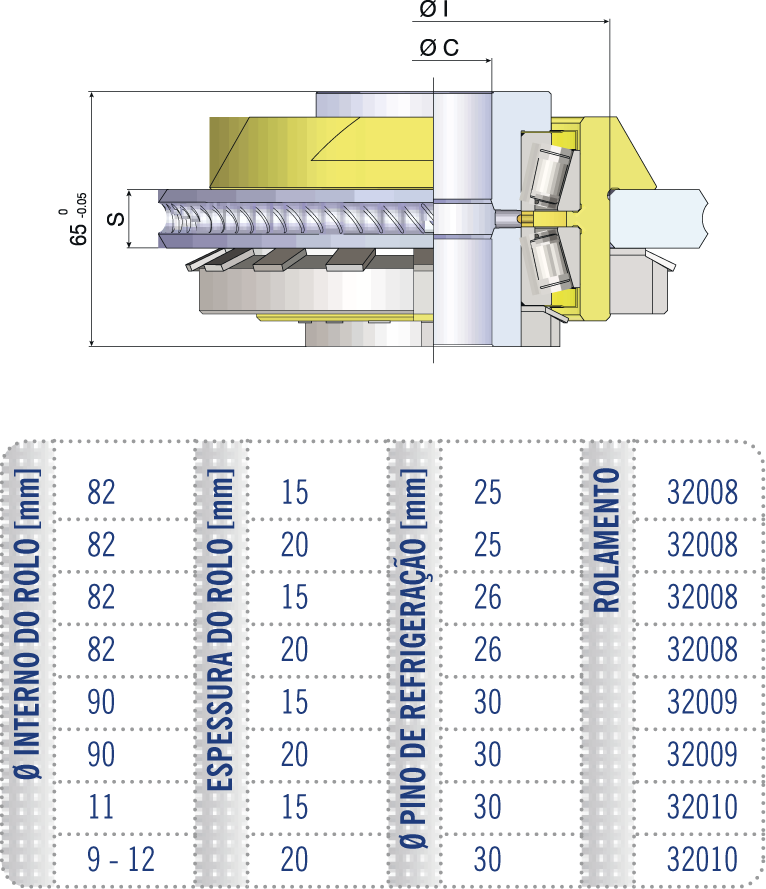

Fixed and Interchangeable Rolling Bearings.

Rolling Bearings are used in the cold rolling process, and carbide rings are mounted on them.

We have two types of Rolling Bearings, the interchangeable and the fixed Rolling Bearings:

Interchangeable Rolling Bearings

Interchangeable Rolling Bearings allow disassembly and replacement of its worn components after use, such as bearings and seals, reusing most parts. The recovery value is less than the purchase of new support.

The lifetime of this support is approximately 1,000t (depending on the process and the product to be laminated).

Dynamic Load: 53000N / Static Load: 71000N

Fixed Rolling Bearings

Fixed Rolling Bearings are shielded. This shield, combined with high-performance components, prevents dust and other external elements from entering its components, which significantly increases its useful life, but this shield prevents its recovery after its useful life.

Dynamic Load: 83000N / Static Load: 78000N

Recommendations for Rolling Bearings.

Suggested Grease:

Premalube Xtreme – NCH Lubrification (temperature between -25 to +150C).

Grease Type: LS-EP2 BP Energrease Stabilizing agent: Lithium – soap Label: DIN 51502 KP2K-20 Service temperature: -20°C to 120°C

Lubrication Frequency: must be done every 4 hours of work.

Cooling water consumption for each cassette: 400 liters per hour