CNC Grinding Machines

AT7xxE CNC

AT7xxE CNC series grinding machine are specially designed for the demand of the tool shops of the modern rolling mills. The various sizes of the range can cover from rings of finishing blocks to composite cylinders of 2 meters length.

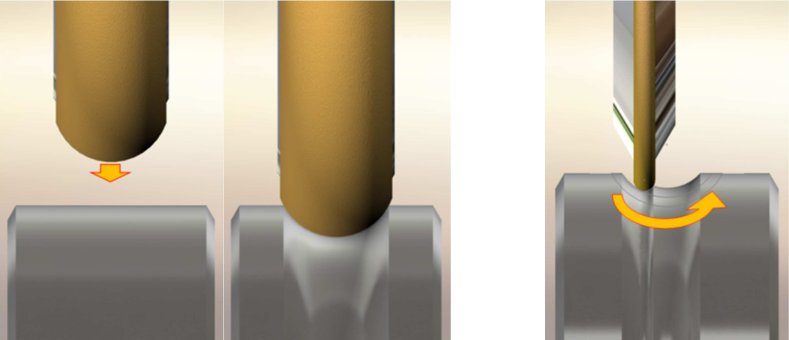

The advanced SIEMENS 840 SL control, with set up for internet remote assistance, is able to grant the maximum accuracy and flexibility to these grinders. The machines can operate both in contour and plunge grinding.

The machine can operate both in contour and plunge grinding. When operated in contour, the machine can perform all possible profiles basically with the same grinding wheel.

The ring grinding machine is also available in the combined version. The AT710 EN CNC performs the grinding, notching and marking operation in the same machine.

AT711 E CNC

This machine is specialized in grinding the Tungsten Carbide rolls of no twist finishing block.

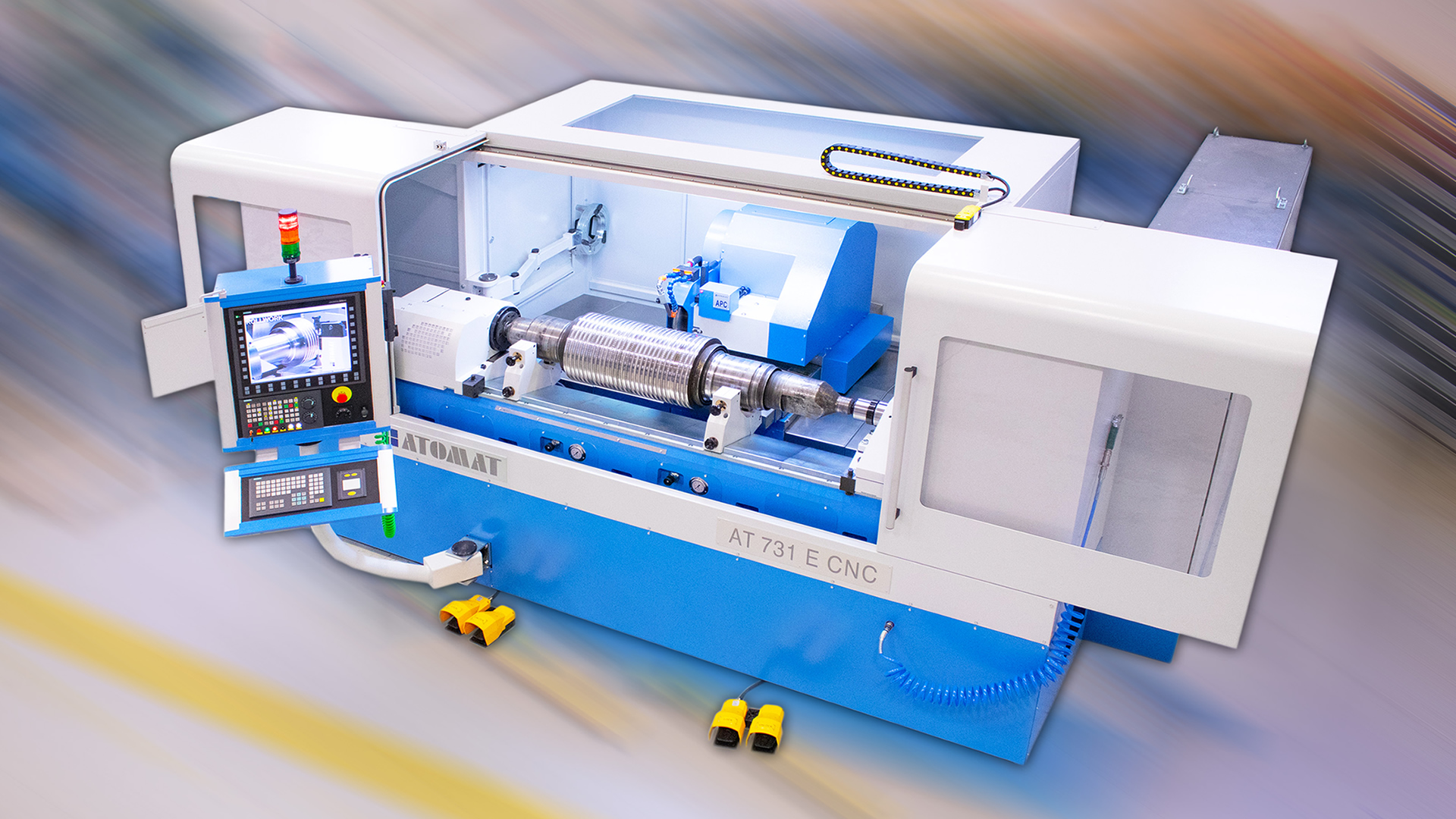

AT731 E CNC

This machine is specialized in grinding the Tungsten Carbide rolls of no twist finishing block as well as composite cylinders.

AT710 EN CNC

The AT710 EN CNC performs the grinding, notching and marking operation in the same machine.

AT701 E CNC

The AT701 E is a CNC grinding machine specifically designed for grinding carbide rolls for cold rolling micro and standard cassettes and guide rollers (Titanium or Tungsten Carbide) for wire hot rolling.